Dubai, June 18th, 2024 — for immediate release

LEAP 71, a Dubai-based AI engineering company, announced today the successful test firing of a liquid rocket engine created entirely through Noyron, the company’s Large Computational Engineering Model. The engine was designed autonomously without human intervention and then 3D-printed in copper. The rocket thruster was successfully hot-fired at a rocket test stand in the UK.

The engine with 5 kN (500 kg / 1124 lbf) of thrust, generated the expected 20,000 horsepower, and completed all tests, including a long duration burn.

Josefine Lissner, Aerospace engineer, and Managing Director of LEAP 71 said: “This is an important milestone for us, but also for the entire industry. We can now automatically create functional rocket thrusters and directly move to practical validation. From final specification to manufacturing, the design of this engine took less than 2 weeks. In traditional engineering, this would be a task of many months, or even years. Each new engine iteration takes only minutes. Innovation in space propulsion is hard, and costly. With our approach, we hope to make space more accessible for everyone.”

The generated engine uses cryogenic Liquid Oxygen (LOX) and Kerosene as propellants. The copper combustion chamber is regeneratively cooled and the injector head features state-of-art coaxial swirler to mix the propellants.

Lin Kayser, co-founder of LEAP 71 said: “Our company is at the forefront of the new field of Computational Engineering, where sophisticated machines can be designed without manual work. The paradigm significantly accelerates the pace of innovation for real-world objects. The fact that the Noyron thruster operated nominally on the first try, confirms that the approach is working. The method can be applied to any field of engineering.”

LEAP 71 worked with leading German metal 3D printing company AMCM on the production of the thruster. It was then post-processed at the University of Sheffield and prepared for the test. The hot fire was performed at Airborne Engineering, Ltd. in Westcott, UK.

LEAP 71 will use the data from the test to further advance Noyron. The company is working with leading aerospace companies in the US, Europe and Asia on the commercialization of the the resulting rocket engines.

About LEAP 71

LEAP 71 is a company based in Dubai, UAE, founded by aerospace engineer Josefine Lissner and serial entrepreneur Lin Kayser.

LEAP 71’s mission is to radically advance the progress in engineering through the new field of Computational Engineering. The company uses sophisticated software algorithms to build physical products. LEAP 71 has developed the Large Computational Engineering Model Noyron, which is considered the most advanced model available.

LEAP 71 works with customers all over the world, including the US, Korea, Europe, and China to design products in fields ranging from aerospace and electric mobility, to heat exchangers.

LEAP 71 has open-sourced a significant part of the technology stack, including PicoGK (“peacock”), a compact and robust geometry kernel, that enables the creation of very complex physical objects.

Most of LEAP 71’s parts are 3D printed on advanced industrial Additive Manufacturing machines.

LEAP 71 June 2024 hot fire backgrounder

Achievements

- First rocket engine built entirely through a computational model without human intervention

- Likely the shortest time from spec to manufacturing for a new rocket engine (2 weeks, usually this process takes many months in manual engineering using CAD)

- First liquid fueled rocket engine developed in the United Arab Emirates

- Engine worked on the first attempt

- No CAD was used in the design

Rocket thruster project

The development of the Noyron TKL-5 rocket thruster, which was successfully hot fired in June 2024, is an internal LEAP 71 project to showcase the capabilities of the Noyron Large Computational Engineering Model.

The design phase of the thruster took less than 2 weeks from final specification to send-off to manufacturing. The generation of new design variations takes less than 15 minutes on a regular computer. The thruster geometry was printed at AMCM, a leading metal 3D printing company in Germany.

LEAP 71 partnered with the University of Sheffield, UK, and Airborne Engineering, a UK test site provider, for the hot fire campaign. The University of Sheffield’s UK Race to Space team provided a wealth of practical feedback, and completed all the post-machining steps and instrumentation required to move the thruster to the test stand. Technical advisor Sam Rogers, Chief Design Officer at Gravity Industries, provided important guidance throughout the project.

The rocket engine

LEAP 71 chose a thrust level of 5kN (equivalent to 500 kg / 1120 lbs lift mass or 20,000 horsepower). This is a relatively compact engine, which would be suitable for a final kick stage of an orbital rocket.

The thruster runs on cryogenic Liquid Oxygen (LOX) and Kerosene, a combination that is used by many advanced rocket systems, including the SpaceX Falcon 9 and the venerable Saturn V moon rocket. LEAP 71 intentionally made that selection despite the propellants being more challenging to operate than others commonly used for small engines.

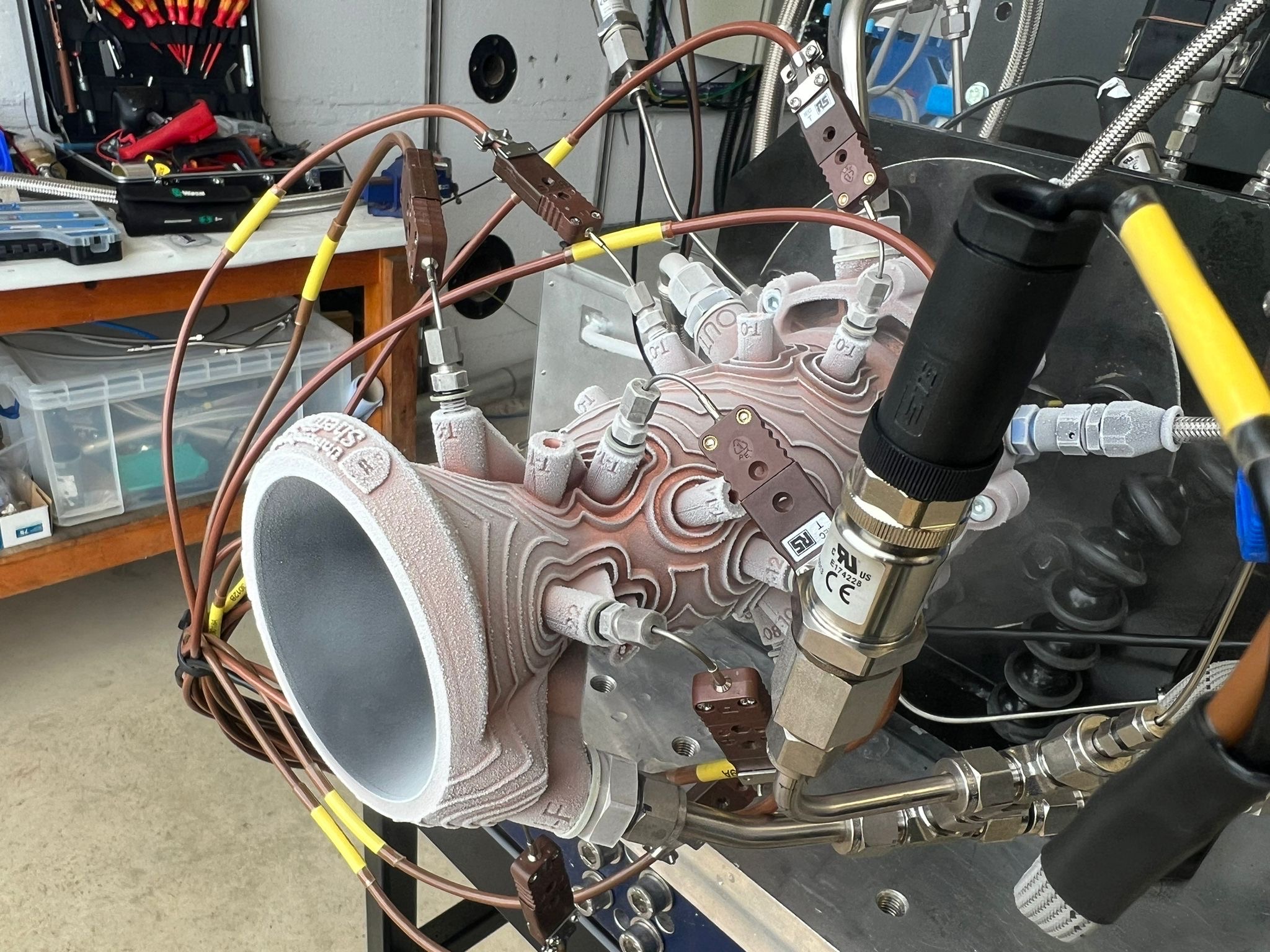

The engine was printed from copper (CuCrZr) using an EOS M290 metal printer. Copper has a low melting point, but enables compact high-performance engines, when actively cooled. If cooling failed, it would melt immediately.

The engine uses thin cooling channels that swirl around the chamber jacket, with a variable cross sections as thin as 0.8mm. The Kerosene is pressed through the channels to cool the engine and prevent it from melting. Both propellants are then injected into the combustion chamber. The combustion temperature inside the engine is around 3000ºC, whereas the engine surface stays below 250ºC, because of the active cooling.

The propellants are injected into the engine using a coaxial swirl injector head. This injector type is considered the most advanced.

Additional film cooling is provided by directing a portion of the fuel through tiny holes near the wall of the combustion chamber.

A multitude of measurement ports for temperature and pressure data enable information to flow back into the Noyron computational model.

The test

The hot fire was conducted in Westcott, UK, at the test site of Airborne Engineering on Friday, June 14, 2024. The engine was hot fired for an initial 3.5 seconds using an oxidizer to fuel ratio of 1.8, which is lower than the nominal 2.3. By using less oxidizer, the engine burns slightly less hot. After confirming that the engine performed well and all temperatures were in the expected range, the engine was tested for a full 12 second long-duration burn at a nominal oxidizer-to-fuel ratio of 2.3.

The engine performed as expected. It achieved steady-state, which means it can essentially be operated as long as needed. The burn time was only limited by the fuel supply at the test site.

Post analysis

The engine was disassembled at the University of Sheffield the next day, and careful inspection confirmed that it remained fully intact. The thruster will stay in the UK for future tests. Initial analysis of the data show that the pressure drop (the resistance) of the cooling channels was higher than modeled, which is due to the actual surface roughness of the 3D print. The team will post-smooth the existing engine while Noyron’s cooling channel logic has already been updated to improve predictions and the design for future engines.